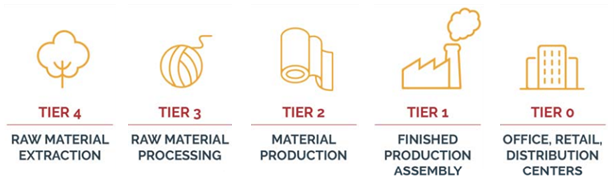

In contrast to our contractual suppliers, the tiers beyond (our suppliers’ suppliers) are dynamic and in large numbers. Our suppliers’ suppliers are not directly in contact with hummel and are selected based on the needs of our contractual supplier and the individual products they offer to a negotiated price. These can be dyeing houses, print houses, trim suppliers, dye suppliers, polybag suppliers, cardboard box suppliers, fabric mills, yarn mills and raw material providers. We require that our tier 1 supplier, often the assembly factory and the factory we have a contractual relationship with, pass our code of conduct to them, as well as instilling their own requirements towards their suppliers. While our overview and leverage is limited, our responsibility for the lower tiers in our value chain remains. Several of our suppliers have vertical set-ups which means that they process the raw material, knit or weave the fabric, dye, print and cut the fabrics, and finish the products themselves, we also use nominated supplier in some cases.

Currently we are in the process of mapping our suppliers beyond tier 1, focusing on the value chains of the bestselling items. This is naturally a constantly changing goal post, with new products being introduced regularly. The mapping is therefore a continuous process to 'capture' the majority of our supply chain.

We are furthermore mapping and monitoring our downstream value chain as we are increasingly taking responsibility for the end-of-life process of our textiles by investing in reselling and recycling.

Illustration shows the upstream supply chain

Koszulki

Koszulki Bluzy z kapturem i bluzy

Bluzy z kapturem i bluzy Spodnie

Spodnie Spodenki

Spodenki Zestawy

Zestawy Kurtki

Kurtki Bielizna sportowa

Bielizna sportowa Stroje kąpielowe

Stroje kąpielowe Bielizna i skarpetki

Bielizna i skarpetki

Sneakersy

Sneakersy Buty treningowe

Buty treningowe Buty halowe

Buty halowe Buty do piłki ręcznej

Buty do piłki ręcznej Sandały i klapki

Sandały i klapki Okulary przeciwsłoneczne

Okulary przeciwsłoneczne Torby

Torby Czapki beanie i czapki z daszkiem

Czapki beanie i czapki z daszkiem Rękawiczki i ocieplacze na szyję

Rękawiczki i ocieplacze na szyję Koszulki

Koszulki Bluzy z kapturem i bluzy

Bluzy z kapturem i bluzy Leginsy

Leginsy Biustonosze sportowe

Biustonosze sportowe Topy

Topy Spodnie

Spodnie Spodenki i spódnice

Spodenki i spódnice Kurtki

Kurtki Bielizna sportowa

Bielizna sportowa Bielizna i skarpetki

Bielizna i skarpetki

Sneakersy

Sneakersy Buty treningowe

Buty treningowe Buty halowe

Buty halowe Buty do piłki ręcznej

Buty do piłki ręcznej Sandały i klapki

Sandały i klapki Okulary przeciwsłoneczne

Okulary przeciwsłoneczne Torby

Torby Czapki beanie i czapki z daszkiem

Czapki beanie i czapki z daszkiem Rękawiczki i ocieplacze na szyję

Rękawiczki i ocieplacze na szyję Body

Body Bluzy

Bluzy Spodnie i legginsy

Spodnie i legginsy Zestawy

Zestawy Krótkie spodenki

Krótkie spodenki Sukienki

Sukienki Odzież wierzchnia

Odzież wierzchnia Skarpetki

Skarpetki Wełna

Wełna Kominiarki i rękawiczki

Kominiarki i rękawiczki Torby i akcesoria

Torby i akcesoria

Bluzy z kapturem i bluzy

Bluzy z kapturem i bluzy Spodnie i legginsy

Spodnie i legginsy Koszulki i topy

Koszulki i topy Spodenki

Spodenki Zestawy

Zestawy Stroje kąpielowe

Stroje kąpielowe Sukienki i spódnice

Sukienki i spódnice Odzież wierzchnia

Odzież wierzchnia Wełna

Wełna Bielizna i bielizna nocna

Bielizna i bielizna nocna Skarpetki

Skarpetki Czapki i rękawiczki

Czapki i rękawiczki Torby i akcesoria

Torby i akcesoria

Sneakersy

Sneakersy Buty zimowe

Buty zimowe Buty gumowe

Buty gumowe Buty halowe

Buty halowe Buty do piłki ręcznej

Buty do piłki ręcznej Buty do piłki nożnej

Buty do piłki nożnej Sandały i klapki

Sandały i klapki Buty dla początkujących

Buty dla początkujących Klapki

Klapki Komplety termiczne

Komplety termiczne Fleece

Fleece Kurtki

Kurtki Kombinezony przeciwdeszczowe

Kombinezony przeciwdeszczowe Kurtki zimowe

Kurtki zimowe Kombinezony narciarskie

Kombinezony narciarskie Spodnie wierzchnie

Spodnie wierzchnie Koszulki i topy

Koszulki i topy Koszulki

Koszulki Zestawy

Zestawy Spodenki

Spodenki Spodnie i legginsy

Spodnie i legginsy Odzież wierzchnia

Odzież wierzchnia Koszulka piłkarska

Koszulka piłkarska Koszulki treningowe

Koszulki treningowe Spodnie do piłki nożnej

Spodnie do piłki nożnej Spodenki do piłki nożnej

Spodenki do piłki nożnej Zestawy treningowe

Zestawy treningowe Kurtki do piłki nożnej

Kurtki do piłki nożnej Skarpety do piłki nożnej

Skarpety do piłki nożnej Bielizna piłkarska

Bielizna piłkarska Piłki do piłki nożnej i akcesoria

Piłki do piłki nożnej i akcesoria

koszulki do piłki ręcznej

koszulki do piłki ręcznej Koszulki treningowe

Koszulki treningowe Handball pants

Handball pants Buty do piłki ręcznej

Buty do piłki ręcznej Szorty do piłki ręcznej

Szorty do piłki ręcznej Piłka ręczna i akcesoria

Piłka ręczna i akcesoria

Koszulki i topy

Koszulki i topy Biustonosze sportowe

Biustonosze sportowe Koszulki

Koszulki Szorty

Szorty Leginsy

Leginsy Spodnie treningowe

Spodnie treningowe Kurtki treningowe

Kurtki treningowe Buty treningowe

Buty treningowe Koszulki i topy

Koszulki i topy Koszulki

Koszulki Spodnie i leginsy

Spodnie i leginsy Szorty

Szorty Kamizelki i kurtki

Kamizelki i kurtki Akcesoria

Akcesoria